loading

The usage of titanium tubes in automobiles is primarily focused on exhaust systems due to the unique properties of titanium. Here are some key applications of titanium tubes in the automotive industry:

Exhaust Systems: Titanium tubes are used in high-performance and sports cars for exhaust systems. Titanium's high strength-to-weight ratio allows for the construction of lightweight and durable exhaust components. Titanium's heat resistance also enables the exhaust system to withstand high temperatures and improve overall performance.

Intake Systems: Titanium tubes are sometimes utilized in intake systems to improve airflow and reduce weight. The lightweight nature of titanium allows for better engine performance and fuel efficiency.

Suspension Components: Titanium tubes can be used in suspension systems to reduce weight while maintaining strength and durability. The use of titanium in suspension components can improve handling, responsiveness, and overall vehicle performance.

Engine Components: While less common, titanium tubes can be used in certain engine components such as connecting rods and valves. Titanium's high strength and heat resistance make it suitable for these high-stress applications.

It's worth noting that the usage of titanium tubes in automobiles is often limited to high-end or performance vehicles due to the higher cost of titanium compared to other materials. However, advancements in manufacturing processes and cost reduction efforts may lead to wider adoption of titanium in various automotive applications in the future.

牌号 Grade | 状态 Status | 室温力学性能 Room-Temperature Mechanical Properties | |||

抗拉强度Rm/Mpa Tensile Strength Rm/Mpa | 规定非比例延伸强度Rp0.2/Mpa Provisions of Non-proportional Extension Intensity Rp0.2/Mpa | 断后伸长率A50 mm/% Precentage Elongation after Fracture | |||

TA1/GR1 | 退火态 Annealed | ≥240 | 140~310 | ≥24% | |

TA2/GR2 | ≥400 | 275~450 | ≥20% | ||

TA10/GR12 | ≥460 | ≥300 | ≥18% | ||

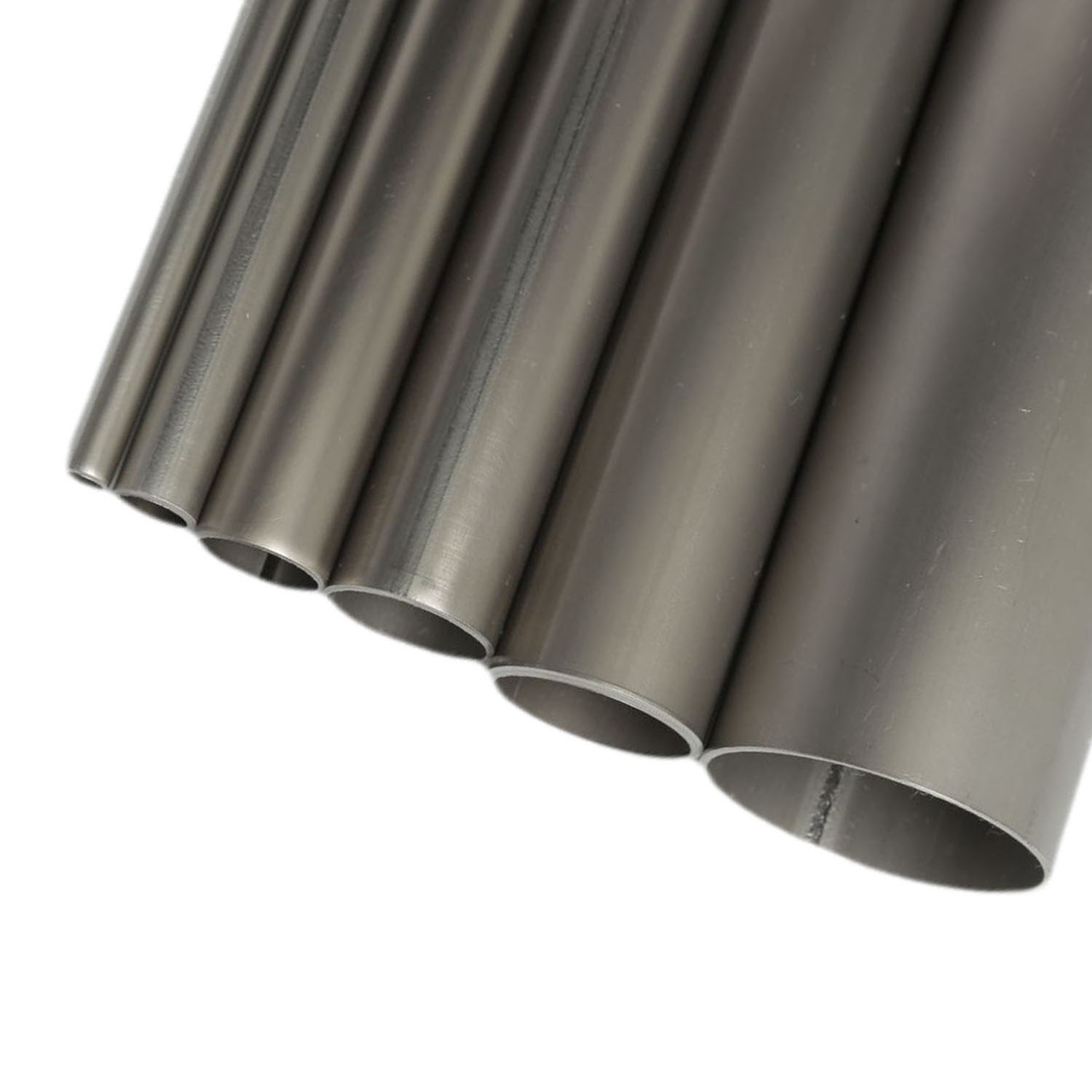

钛焊管 Titanium welded tubes | 6mm to 108mm | 0.3mm to 2mm | ≤ 18000mm 长度可以根据客户要求做成盘管 | TA1/GR1 TA4/GR4 TA2/GR2 TC4/GR5 TA10/GR12 | ASTM B338 ASTM B862 GB/T3625 |