loading

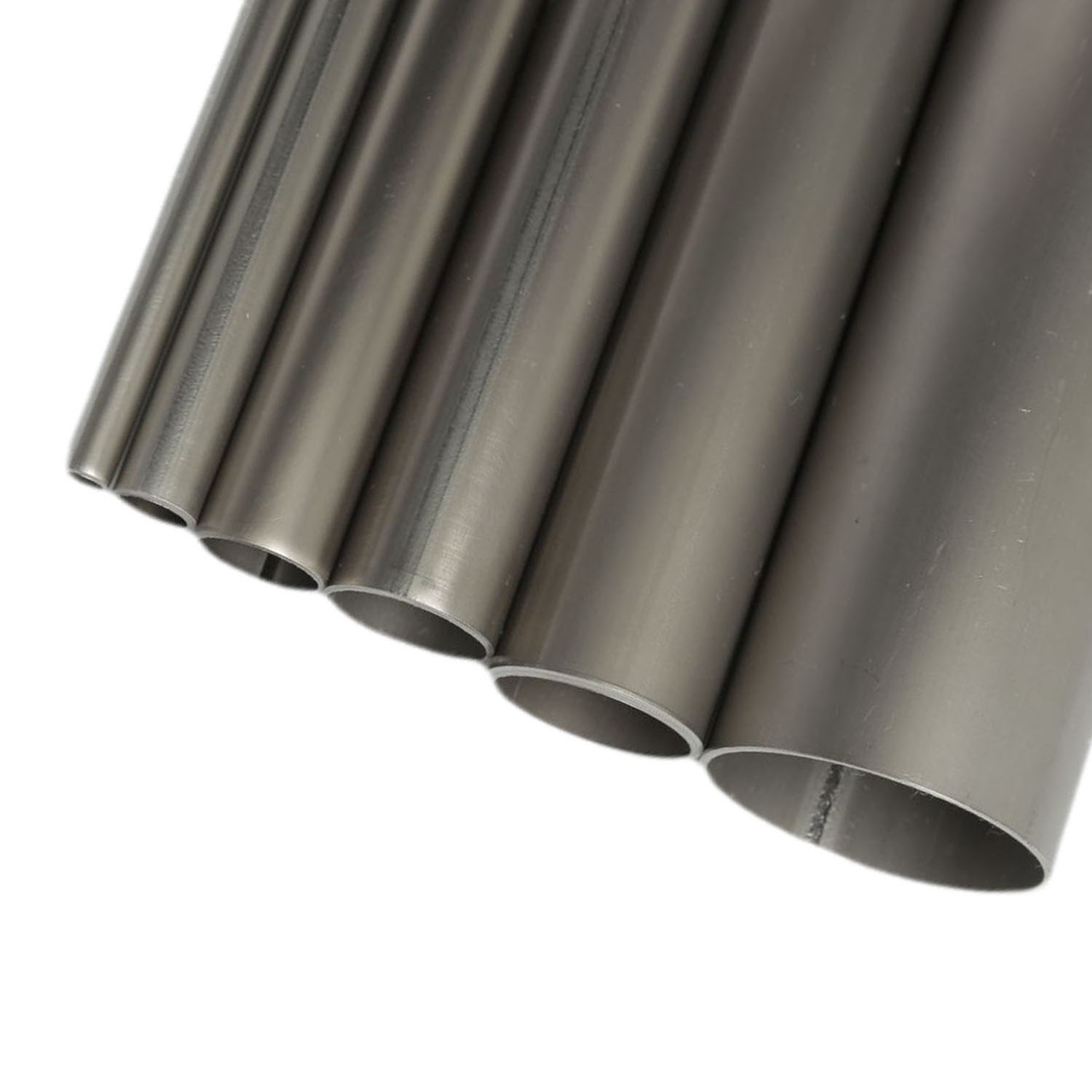

GR5 titanium tube refers to a titanium tube made from Grade 5 titanium alloy, also known as Ti-6Al-4V. This alloy is one of the most commonly used titanium alloys and is composed of 90% titanium, 6% aluminum, and 4% vanadium. GR5 titanium tubes offer several advantages and are widely used in various industries. Here are some key features and applications of GR5 titanium tubes:

High Strength-to-Weight Ratio: GR5 titanium tubes have excellent strength-to-weight ratio, making them significantly lighter than steel tubes while still offering comparable strength. This makes them suitable for applications where weight reduction is crucial, such as aerospace, automotive, and sports equipment.

Excellent Corrosion Resistance: GR5 titanium tubes exhibit exceptional corrosion resistance, even in harsh environments, including seawater, chlorides, and acids. The formation of a protective oxide layer on the surface of the titanium provides excellent resistance to corrosion, erosion, and pitting.

High Temperature Resistance: GR5 titanium tubes can withstand high temperatures without deformation or degradation. They have a melting point of around 1668°C (3034°F) and can operate at elevated temperatures, making them suitable for applications that require heat resistance, such as heat exchangers and exhaust systems.

Biocompatibility: GR5 titanium tubes are biocompatible, meaning they are non-toxic and non-allergenic to the human body. This property makes them widely used in medical and dental implants, where compatibility with the human body is essential.

Weldability: GR5 titanium tubes can be easily welded using various techniques, allowing for easy fabrication and customization. This makes them suitable for applications that require complex shapes or specific dimensions.

Aerospace and Marine Applications: GR5 titanium tubes are commonly used in aerospace and marine industries due to their high strength, corrosion resistance, and lightweight properties. They are used in aircraft structures, engine components, shipbuilding, and offshore structures.

Industrial Applications: GR5 titanium tubes are also used in various industrial applications, including chemical processing, power generation, oil and gas, and desalination plants. Their corrosion resistance and high strength make them suitable for handling corrosive fluids and operating in demanding environments.

It is important to note that GR5 titanium tubes may have different specifications, sizes, and dimensions depending on the specific application requirements. Consulting with a titanium expert or supplier can help in selecting the appropriate GR5 titanium tube for a particular application.

牌号 Grade | 状态 Status | 室温力学性能 Room-Temperature Mechanical Properties | |||

抗拉强度Rm/Mpa Tensile Strength Rm/Mpa | 规定非比例延伸强度Rp0.2/Mpa Provisions of Non-proportional Extension Intensity Rp0.2/Mpa | 断后伸长率A50 mm/% Precentage Elongation after Fracture | |||

TA1/GR1 | 退火态 Annealed | ≥240 | 140~310 | ≥24% | |

TA2/GR2 | ≥400 | 275~450 | ≥20% | ||

TA10/GR12 | ≥460 | ≥300 | ≥18% | ||

钛焊管 Titanium welded tubes | 6mm to 108mm | 0.3mm to 2mm | ≤ 18000mm 长度可以根据客户要求做成盘管 | TA1/GR1 TA4/GR4 TA2/GR2 TC4/GR5 TA10/GR12 | ASTM B338 ASTM B862 GB/T3625 |

The application of titanium tubes in small heat exchangers is mainly due to the excellent corrosion resistance and high strength characteristics of titanium. Here are several aspects of the application of titanium tubes in small heat exchangers:

Chemical Industry: Small heat exchangers are widely used in the chemical industry for processes such as heating, cooling, and evaporation. Due to the presence of various corrosive media in the chemical industry, the corrosion resistance of titanium tubes makes them an ideal choice.

Desalination: Desalination refers to the process of converting seawater into fresh water. Since seawater contains abundant salt and other corrosive substances, titanium tubes have excellent corrosion resistance in desalination equipment and can be used in heat exchangers and evaporators.

Pharmaceutical and Food Industry: The application of titanium tubes in small heat exchangers in the pharmaceutical and food industry is mainly due to the excellent biocompatibility of titanium materials. Titanium tubes can be used in small heat exchangers for heating, cooling, and concentration processes in the production of pharmaceuticals and food.

Aerospace and Marine Industries: Due to the high strength and lightweight characteristics of titanium tubes, they are widely used in small heat exchangers in the aerospace and marine industries. Titanium tubes can be used in cooling systems for aerospace engines, steam generators, and cooling systems for ships.

In summary, the application of titanium tubes in small heat exchangers is mainly due to their corrosion resistance and high strength characteristics, making them suitable for the manufacturing of heat exchangers in industries such as chemical, desalination, pharmaceutical, food, aerospace, and marine.