loading

ASTM B337 and ASTM B338 are both standards established by the American Society for Testing and Materials (ASTM) that relate to titanium and titanium alloy seamless and welded tubes. However, there are some key differences between the two standards. Here is a comparison of ASTM B337 and ASTM B338:

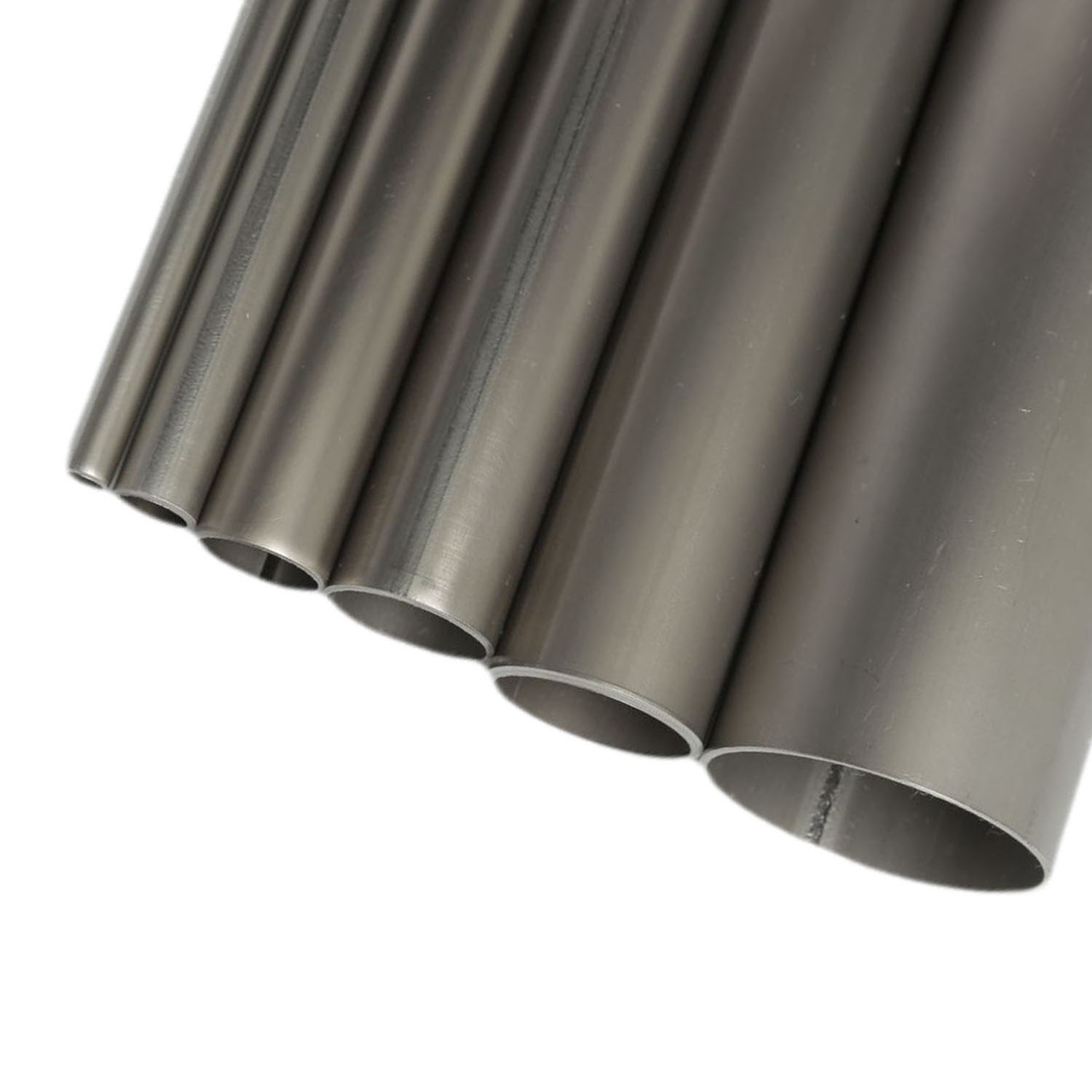

Scope: ASTM B337 covers seamless and welded titanium and titanium alloy tubes intended for general corrosion-resisting and elevated-temperature service. On the other hand, ASTM B338 specifically covers seamless and welded titanium and titanium alloy tubes for condensers and heat exchangers.

Alloy Grades: ASTM B337 includes specifications for various titanium and titanium alloy grades, including Grades 1, 2, 7, 9, 11, 12, 16, 17, 26, and 28. ASTM B338, on the other hand, covers a narrower range of titanium and titanium alloy grades, including Grades 1, 2, 3, 7, 9, 11, 12, 16, 17, 19, 23, and 28.

Chemical Composition: Both standards provide specific chemical composition requirements for the titanium and titanium alloy tubes. However, the composition requirements may differ slightly between ASTM B337 and ASTM B338, depending on the intended application and specific alloy grade.

Mechanical Properties: ASTM B337 and ASTM B338 both specify the mechanical properties, such as tensile strength, yield strength, and elongation, that the titanium and titanium alloy tubes should meet. However, the mechanical property requirements may vary depending on the specific alloy grade and intended application.

Dimensions and Tolerances: Both standards provide guidelines for the dimensions, tolerances, and permissible variations of the titanium and titanium alloy tubes. These specifications include outer diameter, wall thickness, length, straightness, and ovality requirements.

It's important to note that ASTM B337 and ASTM B338 are just two of the many ASTM standards related to titanium and titanium alloys. The choice of which standard to follow depends on the specific application and requirements of the titanium tubes being used. It is recommended to consult the specific standard and consult with materials engineers or suppliers for accurate and up-to-date information.

牌号 Grade | 状态 Status | 室温力学性能 Room-Temperature Mechanical Properties | |||

抗拉强度Rm/Mpa Tensile Strength Rm/Mpa | 规定非比例延伸强度Rp0.2/Mpa Provisions of Non-proportional Extension Intensity Rp0.2/Mpa | 断后伸长率A50 mm/% Precentage Elongation after Fracture | |||

TA1/GR1 | 退火态 Annealed | ≥240 | 140~310 | ≥24% | |

TA2/GR2 | ≥400 | 275~450 | ≥20% | ||

TA10/GR12 | ≥460 | ≥300 | ≥18% | ||

钛焊管 Titanium welded tubes | 6mm to 108mm | 0.3mm to 2mm | ≤ 18000mm 长度可以根据客户要求做成盘管 | TA1/GR1 TA4/GR4 TA2/GR2 TC4/GR5 TA10/GR12 | ASTM B338 ASTM B862 GB/T3625 |